Project category: food raw material processing cold storage, constant temperature and humidity preservation cold storage, cold storage, constant temperature storage, semi-finished product cold storage

Project period: 60 days

Year of cooperation: 2018, 2020

Acceptance date: Phase I July 2018, Phase II January 2020

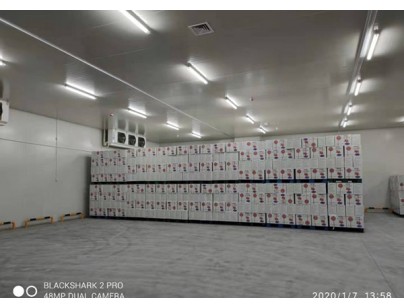

Project requirements: Anhui Qiaqia Food Co., Ltd. specializes in the production and sales of nuts and roasted food, agricultural and sideline products, fried food, puffed food, baked food, etc. With the development of business needs, it is necessary to build a 49500 food raw material processing cold storage. The food processing cold storage is constructed by our company Haoshuang Refrigeration. It is divided into two phases, 19500m³ in the first phase and 30000m³ in the second phase, with a construction period of 60 days.

Project Overview:

(1) The total volume of the newly built automatic constant temperature cold storage and fresh-keeping cold storage in the first phase is 19,500 m³, which was completed and delivered to customers in July 2018.

(2) The newly built automatic constant temperature and humidity fresh-keeping cold storage in the second phase is 12,500 m³, with an adjustable temperature of 0-10℃ and a humidity of ≤50%. Its food cold storage is mainly used to store nuts and dried fruits. The newly built cold storage with a temperature of 0~5℃ and a humidity of ≤50% is 8,750 m³, and independent dehumidification; the constant temperature cold storage with a temperature of 5~15℃ is 8,750 m³, and the humidity is ≤50%, and independent dehumidification; the system operation cooling time is within 3 hours to ensure the temperature uniformity of the entire warehouse.

(3) The food processing constant temperature and humidity fresh-keeping warehouse has a pentahedron body, and the two systems are independent systems with independent operation and control. The overall insulation of the warehouse adopts B1 flame-retardant wall panels, 100mm thick polyurethane double-sided color steel plates on the top plate + 200mm thick high-pressure extruded board floor insulation.

(4) The refrigeration system of the 49,500m³ Qia Qia food processing cold storage uses: Panasonic and Sanyo internationally renowned compressor unit brands, mainly energy saving, low noise, environmental protection, and low maintenance cost as the main indicators, and the refrigerant is environmentally friendly R404A. The valves are all from the internationally renowned Danfoss (Denmark) brand, and the air coolers are Cabeo and Jiesheng.

(5) The food raw material processing cold storage project is equipped with a PLC master control system: the constant temperature and humidity system control must be separated and independently operated, fully automatic constant temperature control and adjustment, the temperature and humidity of the cold storage can be displayed and automatically stored and recorded, and it has the functions of false door closing alarm and remote monitoring.

(6) The first and second phases of the 49,500m³ Qia Qia Food Processing Cold Storage Project have been delivered to customers for use. The cold storage equipment is operating well and is highly recognized by customers.

Design features: All freon environmentally friendly refrigeration, barrel pump liquid supply

Contact: Haocool

Tel: +86 18918087579

Phone: +86 18918087579

E-mail: marina@haocool.com

Add: Building 5, No.499 Minqiang Road, Xinqiao Town, Songjiang District, Shanghai, China